I previously posted this on Reddit, since it reaches more people there (and I didn’t want to post everywhere at once, as it makes it harder to keep up with the comments). Sorry about that.

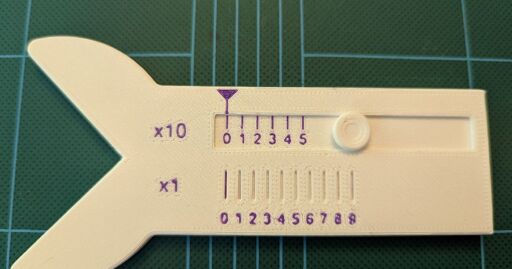

This is a tool for measuring the radius of a circle or fillet from the outside; it uses a moire pattern of slots and lines to enable a direct reading of the values from a vernier scale.

A video of a broken-open version makes it a little easier to see how the moire and vernier features operate: https://i.imgur.com/Ku2nBkq.mp4

More photos of a slightly earlier version are here, including the tool being used for actual readings: https://imgur.com/gallery/moire-vernier-radius-gauge-design-3d-printing-ajy0GBg

I was inspired by this post: https://makerworld.com/en/models/1505553-adjustable-chamfer-gauge#profileId-1575605

which is a gauge which measures chamfers using a sliding probe. The same user had also posted a radius gauge, which worked similarly, but it was much larger, using gears and two racks in it to amplify the motion, which I didn’t initially understand. I asked about it, and he pointed out that, because of the geometry of the probing, the slider only moves a small proportion of the length of the actual radius being measured–about (sqrt(2)-1), or 0.414mm per mm of radius. Since we’re drawing the marks with a 0.4mm nozzle, it’s not really possible to make marks that close together and still have them readable.

So I thought, I bet you could fix that with a vernier scale. And then I had several thoughts all at once–that a lot of people are kind of scared off by vernier scales, and also that I bet you could fix that with 3d printing using the relationship between moire patterns and vernier scales. I don’t think I’ve seen this done before, but it probably wasn’t really practical before 3d printing. Arguably it’s not entirely practical now, as the deep slots and parallax effects can make it a little hard to actually see the markings. But it was a fun experiment, and I think the result is eye-catching enough that it’s probably got some educational value in getting people to actually think about how it is that vernier scales work. (It might even have educational value for things like number theory…e.g., it’s important that the vernier factor involve relatively prime numbers, in this case 9 and 10. Can you see why?)

Anyway, hope folks here find it interesting too.

Very cool. I was thinking about ways of making a potentiometer knob on an audio amp more visually interesting. The moire effect might be one to play around with.

I don’t think I would trust this one in practice, but the effect is interesting. I found it far more necessary to learn the vernier scale with micrometers. It felt much more useful understanding the practical limitations and scope of when to use calipers versus a mic. While there are super accurate calipers, relatively cheap calipers and micrometers are far cheaper and easier for most people to access.

When it comes to radius gauges I trust these more than any of the others I have tried:

I know this kinda isn’t the point, but using it as an excuse to share – the fishing leader line to hold a set like this is key to making them super handy. Unfortunately I have only used micrometers on a few 3d printing projects. Those are more used within the machining realm.

Yeah, it’s definitely not the most precise thing. It’s good to around ±1mm. I tried to measure 1.75mm filament with it, and it just reads 1, not even between 1 and 2, so for critical measurements the physical matches are definitely better.

And yeah, here the vernier effect is not giving very high precision; it’s just giving a way to space the marks out enough to be printable, but indicate movements that are as small as a printed line.